The automotive and insurance industries are experiencing growth, which helps to heighten innovation in AI-powered tools that streamline critical processes. While one area is seeing significant technological advancement in vehicle inspection automation, another area is still struggling with traditionally manual, time-consuming, and tiring processes that have a high probability of human error and subjective assessments, even today.

Recent updates regarding the evolutions in machine learning and computer vision have a great advantage in the industry of automotive vehicle inspections. These technologies are changing the aspect of operations across multiple sectors while focusing on improving customer experience. However, like any evolving technology, AI-based vehicle inspections face certain limitations in their current stage of development.

This article explores the key applications of automated vehicle inspection technology and examines the challenges that still need to be addressed before achieving full automation.

Table of Contents

The evolution of vehicle inspections

For decades, vehicle inspections have been dependent on human inspectors with clipboards and checklists to methodically examine vehicles for damage and mechanical issues.

This approach, while thorough when performed by experienced professionals, can have many disadvantages:

- Time inefficiency: Manual inspections normally require 30-60 minutes per vehicle, which can lead to several operational bottlenecks and an increase in the time taken.

- Subjective assessment: Different inspectors may evaluate the same damage differently, which can lead to a series of inconsistent outcomes

- Documentation challenges: Paper-based systems make record-keeping cumbersome and difficult to reference

- Human error: Even the most diligent inspectors occasionally miss damage or misclassify issues

- Limited scalability: Adding inspection capacity requires hiring and training additional staff

These limitations drove the search for technological solutions that could standardize the process while improving both efficiency and accuracy.

Early digital solutions simply moved paper forms to tablets, but true transformation began with the application of artificial intelligence to the inspection process.

How AI-based vehicle inspections work

Modern AI-powered vehicle inspection systems employ sophisticated convolutional neural networks trained on vast datasets of vehicle images.

These systems analyze photos or video footage through a multi-stage process:

- Vehicle verification – The AI-first confirms that the uploaded image actually contains a vehicle

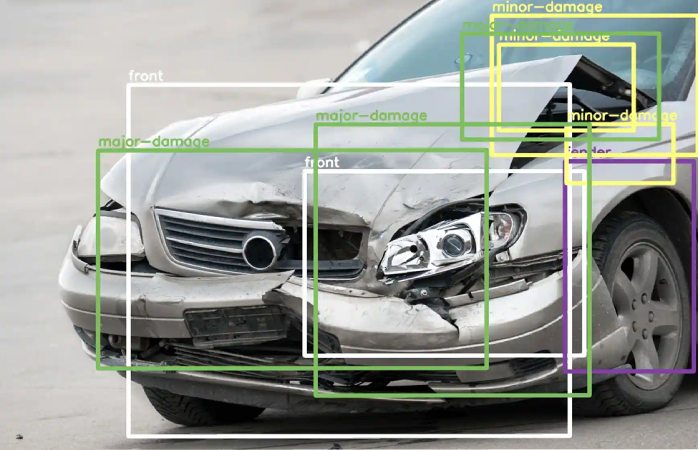

- Damage detection – The system determines whether damage is present on the vehicle

- Location identification – AI pinpoints where the damage is located (front, rear, side, etc.)

- Part recognition – The specific damaged component (door, bumper, windshield, etc.) is identified.

- Severity assessment – Damage is classified by severity (minor, moderate, severe)

This automated approach dramatically reduces inspection time, what used to take hours, now happens in a matter of minutes or even seconds while also significantly improving consistency across assessments.

Most systems can often be connected to your smartphone or dedicated hardware and this can help to make them accessible, literally on your fingertips.

However, it’s important to understand that computer vision technology is still continuously evolving. Current systems may include some disadvantages because of which there are a few challenges that are faced, like variable lighting conditions, camera angles, image resolution, and other environmental factors that can impact assessment accuracy.

Key use cases for AI-powered vehicle inspections

1. Motor insurance claims processing

AI-powered inspection systems are transforming this process in several ways:

- Damage assessment: Automated systems quickly identify and categorize vehicle damage, accelerating the claims process by eliminating wait times for in-person adjusters

- Cost estimation: Advanced algorithms generate repair cost estimates based on identified damage, referencing current parts and labor databases

- Fraud detection: AI can detect inconsistencies between reported damage and visual evidence, flagging suspicious claims for further review

- Digital documentation: These systems create comprehensive digital reports that can be instantly shared with all stakeholders

- Customer self-service: Many solutions enable policyholders to document damage themselves using smartphone apps, initiating claims immediately after incidents

Companies like Inspektlabs have developed specialized solutions that not only detect and classify damage but also recommend whether parts should be repaired or replaced based on damage severity. These systems help in many various sectors as well, which includes creating pricing databases that help to understand and finalize accurate cost estimates, resulting in a streamlined claims process.

Limitations in insurance applications:

Despite these capabilities, current AI inspection systems can also have some disadvantages:

- Internal damage detection: Most systems can only assess visible external damage, missing potential internal structural issues that might be present in moderate to severe accidents

- Repair estimation complexity: Accurate repair cost estimation requires integration with multiple data sources, including OEM parts pricing, regional labor rates, and repair methodology databases

- Regulatory compliance: Insurance claims are subject to specific regulatory requirements that vary by region

Despite these challenges, many companies are implementing AI inspection in their daily work, as they have an advantage and typically report significant improvements in claims processing speed, customer satisfaction, and operational efficiency.

2. Car rental industry applications

The rental car industry faces unique inspection challenges: vehicles must be quickly assessed at both check-out and return, often with customers present and eager to proceed with their journeys. Traditional processes rely on staff members manually inspecting vehicles and completing paper forms—a time-consuming process prone to inconsistency and disputes.

AI-powered inspection systems offer significant advantages in this context:

- Rapid documentation: Complete vehicle inspections can be performed in minutes using smartphone cameras, dramatically reducing customer wait times

- Consistent assessment: Standardized damage evaluation removes the possibility of human variability, ensuring that damage is assessed the same way even though the staff member is not present.

- Enhanced customer experience: Digital reports help to procure a sense of transparency while also reducing customer wait times

- Dispute resolution: Clear before-and-after documentation helps resolve disagreements about damage responsibility

- Fleet optimization: Faster turnaround times mean vehicles spend less time idle between rentals

Limitations in Rental Applications:

The primary challenges for rental companies that are implementing AI inspection systems involve:

- Fraud prevention: Without proper safeguards and protection, there is a possibility that the customers might attempt to manipulate during the inspection process by taking photos at angles that show a higher level of damage than it really is.

- Environmental variables: Lighting conditions and space constraints across diverse rental locations can impact image quality and assessment accuracy

- Integration requirements: AI inspection systems must integrate seamlessly with existing reservation and fleet management systems

Several major rental companies have already implemented AI inspection systems at select locations, reporting reduced customer wait times and fewer damage disputes as key benefits.

3. Used Car Dealerships

The used vehicle market relies heavily on accurate condition assessments to determine fair market value. Traditional appraisal processes are time-consuming and often inconsistent between evaluators.

Automated inspection systems offer several advantages:

Automated inspection systems offer several advantages:

- Standardized valuation: AI helps to create a consistent flow of condition reports that is spread across all vehicles while also eliminating subjective variations between different appraisers

- Market comparison: Advanced systems can automatically compare vehicle condition to market data for accurate pricing

- Customer transparency: Digital reports build trust with potential buyers by providing objective documentation

- Inventory efficiency: Faster inspection processes allow dealers to process more vehicles in less time

- Trade-in optimization: Quick, accurate condition assessments enable dealers to provide more competitive trade-in offers while maintaining profitability

Limitations in used car applications:

Used vehicle assessment presents several challenges for current AI systems:

- Micro-damage detection: Minor dents, paint chips, and scratches that impact valuation may be difficult for AI to consistently identify

- Mechanical assessment: Engine condition, transmission performance, and other mechanical aspects remain difficult to evaluate through visual inspection alone

- Repainting detection: Identifying non-original paintwork, which can significantly impact value, remains challenging for current systems

Despite these limitations, dealerships implementing AI inspection technology report more consistent vehicle valuations and improved customer trust in their condition reports.

4. Leasing company applications

End-of-lease inspections are very important when it comes to leasing companies and their work of assessing the condition of the vehicle, determining excess wear charges, and preparing vehicles for resale or auction.

AI-powered systems offer significant advantages in lease-end scenarios:

- Standardized assessment: Consistent evaluation criteria across all vehicles ensure fair and uniform application of lease terms

- Process efficiency: Dramatically reduced inspection time means vehicles move more quickly from lease-end to remarketing

- Documentation quality: Comprehensive digital records with photographic evidence provide clear justification for any excess wear charges

- Customer transparency: Clear condition reports reduce disputes over end-of-lease charges

- Remote capabilities: Some of the systems allow customers to document their vehicles themselves before returning them in order to help identify potential charges before the formal turn-in process

Limitations in leasing applications:

Leasing companies face several challenges when implementing AI inspection systems:

- Comprehensive evaluation requirements: End-of-lease assessments typically require a thorough evaluation of the interior condition, mechanical systems, and micro-damage detection

- Wear vs. damage assessment: Distinguishing between normal wear and excess wear requiring charges remains challenging for automated systems.

- Contract compliance: Lease agreements contain specific language about acceptable wear that may be difficult to fully translate into AI assessment parameters

Several leasing companies have implemented hybrid approaches that combine AI pre-screening with targeted human review of potential excess wear items.

The future of vehicle inspection automation

While the innovations in today’s time include AI inspection systems, that offer tremendous advantages in areas where, efficiency and customer experience have increased in number, they’re still evolving technologies with certain limitations.Companies at the forefront of this technology, like Inspektlabs, continue to refine their algorithms and expand their capabilities.

Key developments include:

Key developments include:

- Enhanced damage detection: Improved ability to identify minor imperfections and distinguish between types of damage

- Interior assessment: Advanced capabilities for evaluating vehicle interiors, including upholstery condition and functionality of controls

- Mechanical evaluation: Integration with OBD systems to incorporate mechanical diagnostic data alongside visual inspections

- Environmental adaptation: Better performance across variable lighting conditions and environments

- Fraud prevention: More sophisticated verification systems to prevent manipulation

Implementing AI inspection systems: best practices

For the organizations that are considering the adoption of AI inspection technology in the automotive industry, several implementation best practices have emerged:

- Start with hybrid approaches that combine AI assessment with human review for high-stakes decisions.

- Invest in proper training for staff who will use these systems.

- Integrate systems thoroughly with existing business software.

- Establish clear policies for when AI assessments should be supplemented with in-person inspection.

- Continuously review results to identify patterns where the AI may be consistently missing certain types of damage.

- Provide clear customer instructions when implementing self-service documentation options.

Organizations following these principles typically report smoother operations and better results from their AI inspection systems.

Conclusion

AI-powered vehicle inspection systems have occurred with a high advancement in the area of automotive-related industries, offering benefits in efficiency and customer experience. While current technologies have limitations—particularly regarding internal damage assessment, micro-damage detection, and mechanical evaluation—these systems already deliver considerable value across multiple use cases.

For businesses in the automotive sector, the question isn’t whether to adopt inspection automation but how to implement it strategically while understanding its current limitations. As computer vision technologies continue to advance, automated inspection systems will increasingly address current challenges, with companies like Inspektlabs playing a crucial role in shaping the future of vehicle inspection automation.